Metal-Interface takes great care to protect your privacy: when you submit a request or ask a question, your personal information is passed on to the supplier concerned or, if necessary, to one of its regional managers or distributors, who will be able to provide you with a direct response. Consult our Privacy Policy to find out more about how and why we process your data, and your rights in relation to this information. By continuing to browse our site, you accept our terms and conditions of use.

- Dossier on subcontracting Technical article

Subcontracting for Round, Rectangular, Square, Oblong etc. Tubes and Profiles

Sheet metal assemblies can include different shaped tubes and profiles: round, rectangular, square, “L” or “U” shaped, flat or special profiles/tubes.

See all articles - Technical Report on Laser Cutting Technical article

Laser Cutting: How to Organise Your Flow With an Automatic Storage System

The flow of raw materials and cut parts strongly impacts the productivity of laser cutting machines and factory organisation.

See all articles - Technical Report on Laser Cutting Technical article

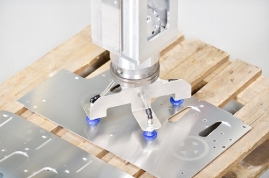

Laser Cutting: Automation of Loading and Unloading

The cutting speed of laser machines has increased considerably in recent years, resulting in a higher volume of parts that can be cut.

See all articles - 2D Laser cutting Technical article

What is important when buying a laser cutting machine?

When purchasing a laser cutting system, there are a number of things to consider, this goes far beyond the purchase price or service intervals. But what exactly has to be taken into consideration?

See all articles - MES-ERP Technical article

Planning: how to reconcile client satisfaction and the realities of a sheet metal industry?

Industrialists, and a fortiori in the sheet metal industry, are subject to production time constraints that affect all the departments in the company in a transversal way: sales representatives, cu

See all articles - Welding technologies Technical article

How to assure an optimal welding quality management?

Manufacturers and subcontractors may be subject to high requirements for traceability and quality of the welds they produce, in particular due to several mandatory manufacturing standards and

See all articles